Sorry for the length, this is what happens when I get excited!

In my other life as a researcher, I've spent a lot of time lately working with 3D Printers. These amazing devices can literally put a bit of material wherever you ask them to in three-dimensional space (including when you ask for something not so smart, take a walk past the DreamVendor sometime and watch the students learning from their mistakes).

There are a number of reasons that the scientific/manufacturing communities are abuzz with excitement over 3D printers:

- You can RAPIDLY turn out a prototype (sometimes 3D printers are called "Rapid Prototyping" machines) of a part you are designing, taking it from the computer screen and placing it in your hands to inspect.

- As materials capabilities improve, 3D printers can manufacture actual parts. We can now print in a variety of plastics, bio materials, and metals at high resolution (thousandths of an inch). In cases where special material properties are needed, we can 3D print a mold, and cast the part out of any material.

- 3D printing is essentially a zero-lost-material manufacturing technique. Manufacturers can save lots by eliminating virtually all scrap in their production processes.

- Complex tooling and machining processes required to make parts typically lead to an economy of scale. Making a one-of-a-kind part requires a custom machine shop to produce it, usually at large expense. With 3D printing, one part costs as much as 100 of them (per part of course).

- 3D printers can revolutionize the replacement parts industry. Imagine a world in which everything you purchase comes with the part files for printing replacement parts. "The washing machine broke and we need a new <insert name of a washing machine part here>." No problem, print it out and install it.

None of these exciting possibilities come close to the true power of 3D printing.

(Original 3D printed concept, could have been made with traditional machining)

More down to earth, the processes of design and manufacture have always been tightly coupled. A designer that draws parts that cannot be made with machinists' tools wouldn't have a job as a designer for long. The job of sculptors and engineers has been to envision a thing trapped within a larger block of material, and to set about "freeing it". This way of thinking is deeply ingrained in most engineers' minds.

After getting my hands on a 3D printer, I started designing and printing parts that looked like parts made using traditional methods, even though I was not limited by my tooling to do so (and I am certainly not alone in this). These design decisions were largely subconscious.

"I suppose it is tempting, if the only tool you have is a hammer, to treat everything as if it were a nail."

Abraham H. Maslow

The Psychology of Science, 1966

The real magic of a 3D printer is freedom of design. We are freed from the requirement to design parts that we can make using the machining capabilities available to us. We no longer need to design parts so that we can machine them from a solid block. Rather than designing for manufacture, we can truly optimize the part for its function.

It's taken a very concentrated effort for me to start scratching the surface of this new world of possibilities. Buried so deeply in my mind that I don't even know it's there is a thought process limiting my ideas to something I can turn out in a machine shop. We don't know how to think in a world of 3D printers that can literally put a bit of material anywhere you want it. We can't get out of our own way!

In an effort to correct this ingrained "thinking shortcoming", we have taken a new direction in my lab. We are letting the computer do the design work for us! Our creative contribution is in what we ask the computer to design and what rules we give the computer to design it. In retrospect, it fits well with what Vannevar Bush was saying in "As We May Think."

"... every time one combines and records facts in accordance with established logical processes, the creative aspect of thinking is concerned only with the selection of the data and the process to be employed and the manipulation thereafter is repetitive in nature and hence a fit matter to be relegated to the machine."

Vannevar Bush

As We May Think, 1945

I think that Bush was getting at the idea of using computers to save time; freeing us up to think about more important things than repetitive data manipulation. However, "computer augmented thinking" goes much further than this. The truth is that the parts we are designing in my lab can only be optimized for their purpose by considering an extremely large number of variables and fundamental physical principles. We are simply not capable of considering the entire complexity of the problem. Enter the man-computer symbiotic thinking. As Englebart said:

"By "augmenting human intellect" we mean increasing the capability of man to approach a complex problem situation, to gain comprehension to suit his particular needs, and to derive solutions to problems... [leading to] more rapid comprehension, better comprehension, the possibility of gaining a useful degree of comprehension in a situation that previously was too complex, speedier solutions, better solutions, and the possibility of finding solutions to problems that before seemed insoluble.

... developing the new methods of thinking and working that allow the human to capitalize upon the computer's help."

Douglas Englebart

Augmenting Human Intellect, 1962

The largely automated design routine we have created is currently spitting out designs that we could have never pictured.

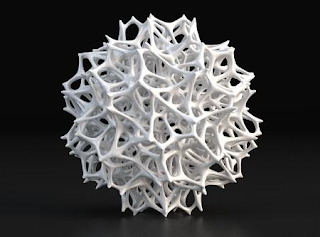

(Sample of what a 3D printer can do that traditional machining cannot)

(New 3D printed concept for the same purpose as above)

(Kudos to Kevin Hoopes)

And they cannot be made (easily) with traditional machining methods. And they work better than anything we've come up with "on our own." Thanks to 3D printers, the constraints on our thinking have been relaxed. I'm very excited to see where this will take us, and I am also excited to see how we might learn to think in a world of 3D printers.

What constrains us?

It's no secret that we live in a world governed by constraints. Some of these constraints are physical, enforced by the universe: "Two objects cannot occupy the same space at the same time." "For every action, there is an equal and opposite reaction." Other constraints are largely man made and I think that 3D printing can serve as a bit of a metaphor for life.

How many times each day are we guilty of doing something a particular way because "that's how we've always done it"? What man made constraints are governing the way that we think? Are these constraints valid or are they holding us back from thinking creatively and reaching better solutions?

No More Teachers' Dirty Looks

Our educational system is built on an industrial model. We have a large number of people that we want to educate, and so we have created a system that attempts to streamline this process and crank out students at a high rate.

If the industrial manufacturing constraints limit our ability to think creatively in terms of designing physical parts, I wonder what the industrial model of education is doing to our ability to think creatively about anything.

Imagine a world in which a person could explore the inner workings of electrical engineering, augmented by studies in technological philosophy, and come out an expert not only in the design of electrical systems, but also a philosophy that guides what they design for the betterment of mankind.

Imagine a student that combines a love of music and engineering, studying both, to design completely new instruments that we've never heard of.

I'd love to meet a person who studied literature, sculpture, thermodynamics, and number theory.

These ideas, much like the parts I first made with a 3D printer, are barely scratching the surface. Once again, I (we) don't know how to think following this paradigm, yet.

Improving Resolution

I opened by poking a little fun at the failures students encounter when working with 3D printers. We rarely get what we were asking for the first time. We rarely design things right the first time. Will the same be true in a framework that allows students to "3D print" their own educational experience? YES! Will it be messy? Absolutely! I argue that it is through these failed conceptions, misprints, and design changes that we learn the most about how the thing works, and where we gain the most power over our designs. We must build a system that encourages experimenting and embraces changing our minds.

What constrains us?

It's no secret that we live in a world governed by constraints. Some of these constraints are physical, enforced by the universe: "Two objects cannot occupy the same space at the same time." "For every action, there is an equal and opposite reaction." Other constraints are largely man made and I think that 3D printing can serve as a bit of a metaphor for life.

How many times each day are we guilty of doing something a particular way because "that's how we've always done it"? What man made constraints are governing the way that we think? Are these constraints valid or are they holding us back from thinking creatively and reaching better solutions?

No More Teachers' Dirty Looks

Our educational system is built on an industrial model. We have a large number of people that we want to educate, and so we have created a system that attempts to streamline this process and crank out students at a high rate.

If the industrial manufacturing constraints limit our ability to think creatively in terms of designing physical parts, I wonder what the industrial model of education is doing to our ability to think creatively about anything.

"... we are coming to recognize that schools are we know them appear designed at every level to sabotage the supposed goals of education. A child arrives at school bright and early in his life. By drabness we deprive him of interests. By fixed curriculum and sequence we rob him of his orientation, initiative and motivation, and by testing and scoring we subvert his natural intelligence.

Schools as we know them all run on the same principles: iron all subjects flat and then proceed, in groups, at a forced march across the flattened plain. Material is dumped on the students and their responses calibrated; their interaction and involvements with the material is not encouraged nor taken into consideration, but their dutifulness of response is carefully monitored.

...It is not that students are unmotivated, but motivated askew... We know virtually nothing of human abilities except as they have been pickled and boxed in schools.

... The human mind is born free, yet everywhere it is in chains. The educational system serves mainly to destroy for most people intelligence, curiosity, enthusiasm, and intellectual initiative and self-confidence. We are born with these. They are gone or severely diminished when we leave school.

... Everything is interesting, until ruined for us. Nothing in the universe is intrinsically uninteresting... Anyone retaining his natural mental facilities can learn anything practically on his own, given encouragement and resources."

Theodor H. Nelson

No More Teachers' Dirty Looks, 1974

3D Printing a Curriculum

The power of a 3D printer is that it gives the designer the ability to put physical material anywhere in a physical space to build a custom part. The only constraints on the designer are his own creativity, and the condition that the part must be able to support itself (i.e. we can't have floating material, yet). Within this fairly open framework, the designer has an extremely large design space to explore.

Imagine an educational system based on a similar framework. We could "3D print" an educational curriculum, allowing the designer to place course material anywhere in an educational space to build a custom curriculum.

Starting to flesh out the framework...

The magic would come when we empower the student to be the designer. We actually do this now, to some extent. Students are able to choose majors, double majors, and minors. Within those majors and minors, students have a finer level of control afforded to them through student-selected elective courses. Students can choose elective courses to build a specialization that interests them or meets their career goals.

The magic would come when we empower the student to be the designer. We actually do this now, to some extent. Students are able to choose majors, double majors, and minors. Within those majors and minors, students have a finer level of control afforded to them through student-selected elective courses. Students can choose elective courses to build a specialization that interests them or meets their career goals.

For those who choose to attend graduate school, the freedom is expanded. Under the guidance of an academic advisor and some department-imposed guidelines, graduate students are able to choose all of the courses that build their curriculum.

3D printers enable a whole new realm of possibilities in custom, one-of-a-kind design. In the same way, students could design an educational curriculum that literally builds a new degree, custom to them, based on the concepts and ideas that speak to their goals and interests.

3D printers enable a whole new realm of possibilities in custom, one-of-a-kind design. In the same way, students could design an educational curriculum that literally builds a new degree, custom to them, based on the concepts and ideas that speak to their goals and interests.

"Don't ask yourself what the world needs. Ask yourself what makes you come alive and then go do that. Because what the world needs is people who have come alive."

Howard Thurman

In Gil Bailie's Violence Unveiled, 1996

Imagine a world in which a person could explore the inner workings of electrical engineering, augmented by studies in technological philosophy, and come out an expert not only in the design of electrical systems, but also a philosophy that guides what they design for the betterment of mankind.

Imagine a student that combines a love of music and engineering, studying both, to design completely new instruments that we've never heard of.

I'd love to meet a person who studied literature, sculpture, thermodynamics, and number theory.

These ideas, much like the parts I first made with a 3D printer, are barely scratching the surface. Once again, I (we) don't know how to think following this paradigm, yet.

Improving Resolution

One of the main trends in improving 3D printers over the years has been the fineness or resolution to which a part can be printed:

Following the same trend, we can incrementally improve the resolution at which students have control over the custom design of their curriculum:

Starting with majors, we expand the freedom to choose elective courses within those majors. Moving from elective courses, we could expand the freedom to choosing all of the courses. Improving further, we could expand the freedom within a course to the selection of different units that apply. Moving to a still finer resolution, we could expand the freedom to selecting the topics and concepts within a specific unit of a specific course. Perhaps we could get to the point where we rid ourselves of the idea of a "course" altogether. After all, "subjects" are artificial:

- Majors

- Electives

- Courses

- Units

- Topics

- Concepts

Starting with majors, we expand the freedom to choose elective courses within those majors. Moving from elective courses, we could expand the freedom to choosing all of the courses. Improving further, we could expand the freedom within a course to the selection of different units that apply. Moving to a still finer resolution, we could expand the freedom to selecting the topics and concepts within a specific unit of a specific course. Perhaps we could get to the point where we rid ourselves of the idea of a "course" altogether. After all, "subjects" are artificial:

"There are no "subjects." The division of the universe into "subjects" for teaching is a matter of tradition and administrative convenience."

Theodor H. Nelson

No More Teachers' Dirty Looks, 1974

Messy Education

When designing a part, we start with the overall objective, and select the components that comprise it, and then the fine details of each component. Along the way, we change our minds, swap out components, alter details, etc. The design process is usually very messy, and the final part is usually only distantly related to the initial prototype.

When designing a part, we start with the overall objective, and select the components that comprise it, and then the fine details of each component. Along the way, we change our minds, swap out components, alter details, etc. The design process is usually very messy, and the final part is usually only distantly related to the initial prototype.

I opened by poking a little fun at the failures students encounter when working with 3D printers. We rarely get what we were asking for the first time. We rarely design things right the first time. Will the same be true in a framework that allows students to "3D print" their own educational experience? YES! Will it be messy? Absolutely! I argue that it is through these failed conceptions, misprints, and design changes that we learn the most about how the thing works, and where we gain the most power over our designs. We must build a system that encourages experimenting and embraces changing our minds.

"Safe? Who said anything about safe? 'Course he isn't safe. But he's good."

C. S. Lewis

The Lion, the Witch, and the Wardrobe, 1950

3D Printers that Print 3D Printers

Another interesting feature of a 3D printer is its capability to self-replicate. This recursive concept can make your head hurt, but it also points out a neat aspect of these devices: they may be the only self-replicating machine that exists.

In the same way, I believe we could use the 3D printing framework at a school to "3D print" another school, which would of course be capable of "3D printing" another school, and so on. Maybe this is just a way of saying that if an idea or method is good, it will spread. What I really intend to say is that we could change the way we do education, drastically.

There is always resistance to tearing down a system that "works." If one student who was able to design his own curriculum in this way chose to do so with a "focus" on teaching and learning, he could apply this method to his teaching and learning. Following a generational model, it wouldn't be very long until we were all thinking and learning this way.

There is always resistance to tearing down a system that "works." If one student who was able to design his own curriculum in this way chose to do so with a "focus" on teaching and learning, he could apply this method to his teaching and learning. Following a generational model, it wouldn't be very long until we were all thinking and learning this way.

"Do not try and bend the spoon. That's impossible. Instead... only try to realize the truth."

"What truth?"

"There is no spoon."

"There is no spoon?"

"Then you'll see, that it is not the spoon that bends, it is only yourself."

Free y(our) mind(s).

More to come, comments welcome!

First of all - BRILLIANT! What a powerful analogy you're exploring, with seemingly endless parallels..

ReplyDeleteSecondively,

"YES! Will it be messy? Absolutely! I argue that it is through these failed conceptions, misprints, and design changes that we learn the most about how the thing works, and where we gain the most power over our designs."

I had a similar reaction and thoughts at several points in reading Ted Nelson... he seems beyond frustrated with the paradigm-limited attempts to leverage technology to perpetuate broken systems (rightly so), but also shows no patience or appreciation for mistakes along the way. In fact, at one point he seemed disdainful toward those not making light-speed strides into a new dimension. Indeed, it is early mistake-fraught attempts into new arenas that I think help us understand needed changes in direction and approach, build awareness and a new level of understanding of the needs and opportunities, and set the stage for true advancement. And, by the way, the mistakes don't just inform the process and systems advancement - they inform our learning about our own learning and awareness. Powerfully valuable.

First of all - BRILLIANT! What a powerful analogy you're exploring, with seemingly endless parallels..

ReplyDeleteSecondively,

"YES! Will it be messy? Absolutely! I argue that it is through these failed conceptions, misprints, and design changes that we learn the most about how the thing works, and where we gain the most power over our designs."

I had a similar reaction and thoughts at several points in reading Ted Nelson... he seems beyond frustrated with the paradigm-limited attempts to leverage technology to perpetuate broken systems (rightly so), but also shows no patience or appreciation for mistakes along the way. In fact, at one point he seemed disdainful toward those not making light-speed strides into a new dimension. Indeed, it is early mistake-fraught attempts into new arenas that I think help us understand needed changes in direction and approach, build awareness and a new level of understanding of the needs and opportunities, and set the stage for true advancement. And, by the way, the mistakes don't just inform the process and systems advancement - they inform our learning about our own learning and awareness. Powerfully valuable.

all good points, but I think the framework for the custom printed education system is already in place, the internet. If anyone watched every TED lecture and instructional youtube video online they would probably be as rounded as Da Vinci. And you can do this from your home, or in between classes. For free. If you really wanted to learn something it doesn't take a university and thousands of dollars. The real question at this point is why everyone ISN'T slightly knowledgeable in a number of fields.

ReplyDeleteI think the idea of 3D printers leading to a whole new way of thinking is very interesting. It would take some time to adjust to design with practically no manufacturing constraints but would come with developing new shapes and processes that we could not even imagine. Speaking of TED lectures, I saw one that featured an architect talking about a process he developed on the computer of folding a cube over and over to create shapes that are extremely intricate and he aimed to use them in a column. He basically gave the program certain constraints and had the computer repeat this "fold" over and over until he created a shape that would be nearly impossible to design or draw by hand. It seemed pretty similar to the idea of "computer augmented thinking."

ReplyDeletehttp://www.ted.com/talks/michael_hansmeyer_building_unimaginable_shapes.html